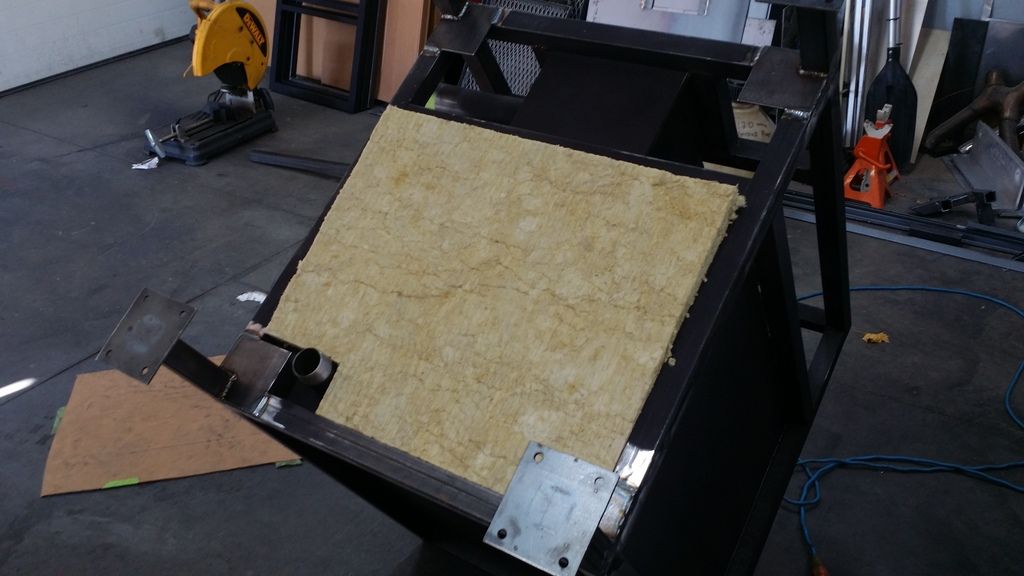

Spent a better part of a saturday cutting tubing and angle, 3 people, about 7 hours later and it was basically all cut and edges dressed. I noticed that filling the tubes with insulation was optional, and being I did not have the roxul insulation yet I simply purchased blow-in style insulation and filled a 5 gallon bucket and started stabbing tubes into the insulation untill they were packed full. I hope the insulation will hold up but being its optional I figure it wont be the end of the world either way.

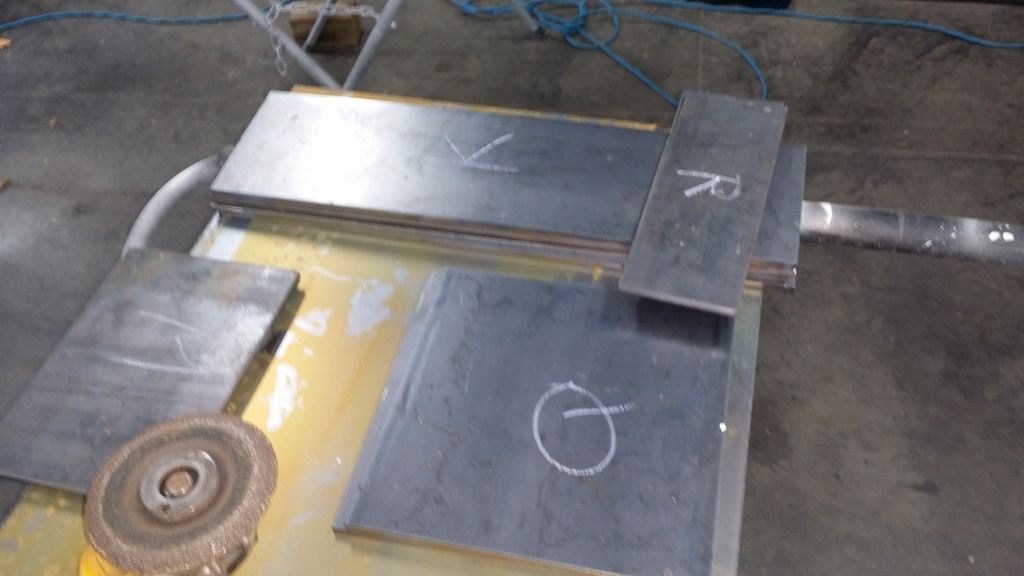

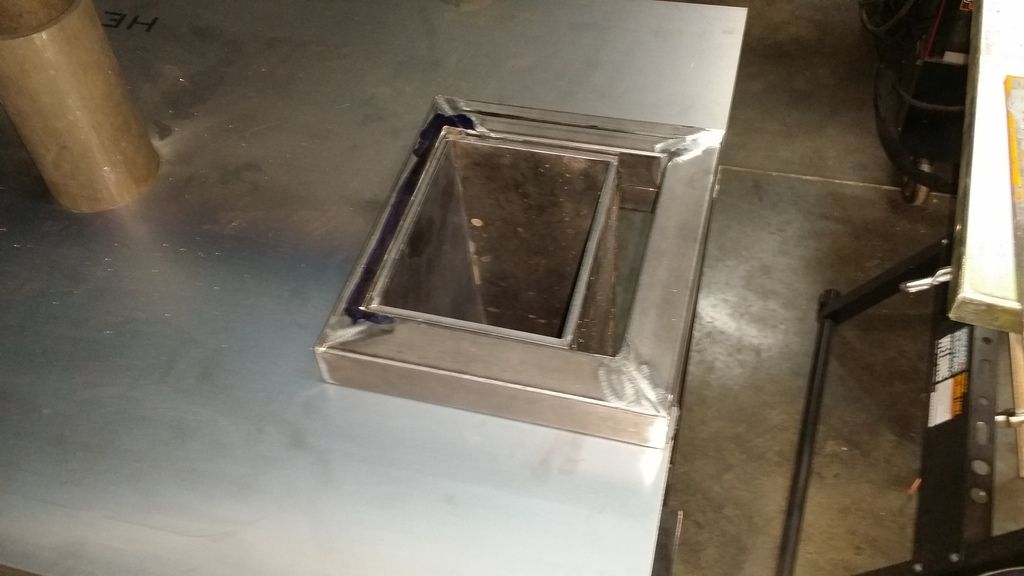

We still had some extra time and we made great progress so after a quick pizza delivery and a beer break we started welding, ended up with 2 nearly complete frames, door curbs, and partially completed racks and slides. I was very impressed with our productivity for 1 day to say the least. We sent the sheetmetal out to a local dude who does cnc plasma cutting in his garage "found him on craigslist" since the idea of cutting 35+ pieces from 6 sheets of 4x8 sounded very time consuming. and a modest charge of around 120 dollars, 60/piece to have the pieces cut straight and accurately sounds like a deal compared to the alternative. I will have a ton of questions for you guys who have built one already Im sure!